ADC-66 Conveyor Dish Machine

High or low temperature conveyor dishwashing machine that features overflow scraping.

Featuring a pre-scrap tank, the high-powered ADC-66 conveyor dish machine has the ability to save on time and labor while producing excellent results.

More Product Info

Features ↓ Specifications ↓ Notes ↓ Dimensions ↓ Options & Accessories ↓

- Reliable pre-wash

- Unrivaled cleaning ability

- Best performance of all list 66″ conveyors

- Rated for dual sanitizing

- 66% less water than industry average

- 244 racks per hour – .49 gallons water per rack

- Autofill and shut-off standard

- Water curtain rinseability

- Activates prior to final rinse

- initiates the rinsing process and acts as a shield

- Captive end caps

- Flips open, snaps shut

- Quick fast clearing of spray arms

- shortens the cleaning process and eliminates down time

- Dual – fail safe heater control

- Precise water control mechanism

- Only allows heaters to operate when tank is full

- Unaffected by heavy soil, water action, strong chemicals, and lime build up

- Fail safe conveyor system

- Slip clutch design – stops rack movement

- Once removed operation easily resumes

- Eliminates damaged racks

- Pre-wash scrap basket

- V construction

- Keeps soil in tray

- Protects pump

- Drain pump filter

- 2 stage pump strainer

- Eliminates wash pump obstructions and clogged jets

- Functions as drains stopper

Capacities

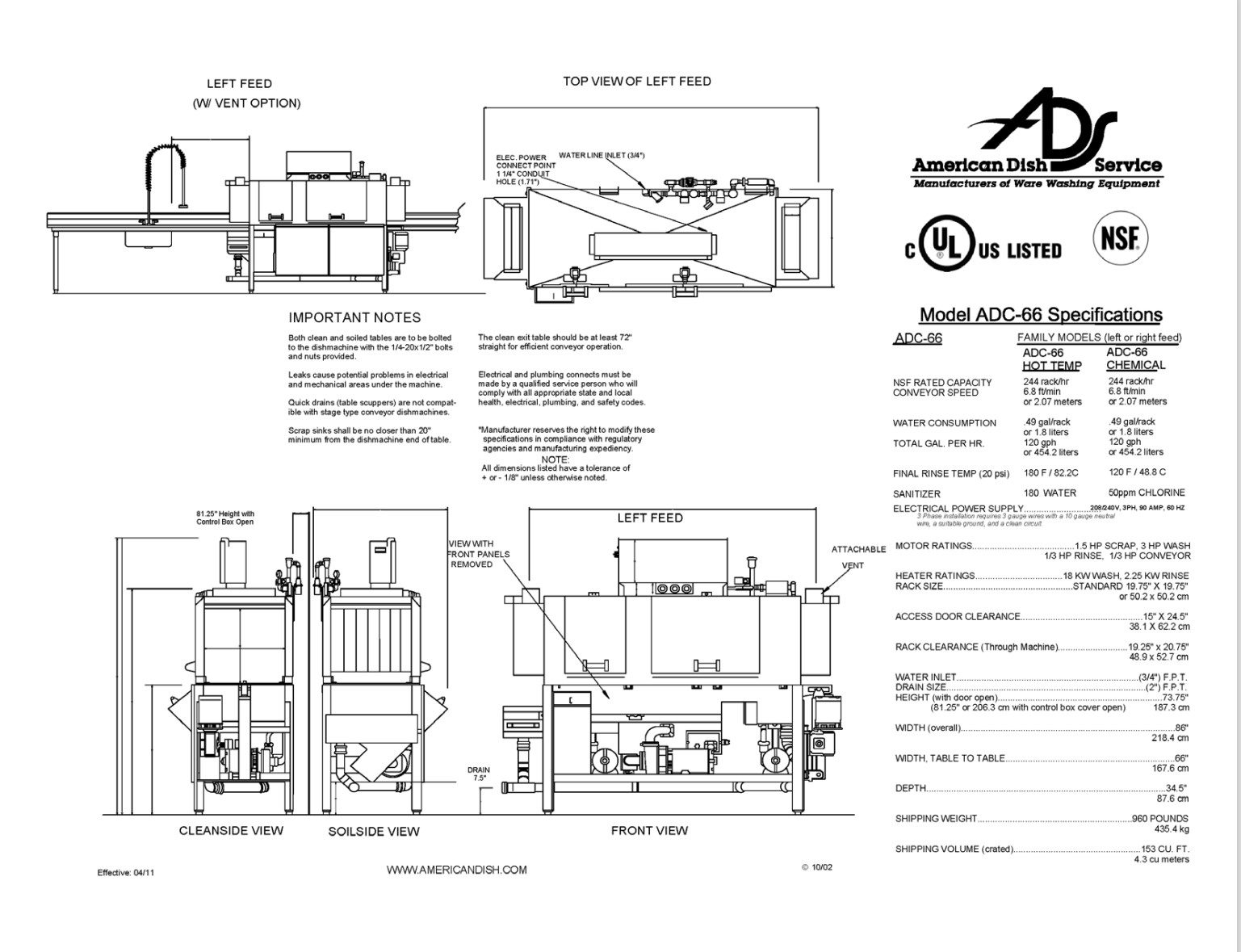

NSF Rated Capacity: 244 rack/hr

Conveyor Speed: 6.8 ft/min or 2.07 meters

Motor Ratings

Scrap: 1.5 horsepower

Wash: 3 horsepower

Rinse: 1/3 horsepower

Conveyor: 1/3 horsepower

Water Consumption

Gal per rack: .49 gpr or 1.8 liters

Temperatures

ADC-66 Hot Temp Model Wash: 160°F

ADC-66 Chemical Model Wash: 120°F

ADC-66 Hot Temp Rinse: 180 F

ADC-66 Chemical Rinse: 120 F

Heating

Wash: 18 kW

Rinse: 2.2 kW

Sanitizer

ADC-66 Hot Temp Model: 180 Water

ADC-66 Chemical Model: 50ppm Chlorine

- Both clean and soiled tables are to be bolted to the dishmachine with the 1/4-20×1/2″ bolts and nuts provided.

- Leaks cause potential problems in electrical and mechanical areas under the machine.

- Quick drains (table scuppers) are not compatible with stage type conveyor dishmachines.

- Scrap sinks shall be no closer than 20″ minimum from the dishmachine end of table.

- The clean exit table should be at least 72″ straight for efficient conveyor operation.

- Electrical and plumbing connects must be made by a qualified service person who will comply with all appropriate state and local health, electrical, plumbing, and safety codes.

Warning: Plumbing and electrical connections should be made by qualified personnel who will observe all the applicable plumbing, sanitary and safety codes and the National Electrical Code. Also, due to an ongoing value analysis program, specifications contained in this catalog are subject to change without notice.

*Manufacturer reserves the right to modify these specifications in compliance with regulatory agencies and manufacturing expediency.

Power Supply

208/240V

3PH

90 AMP

60 HZ

3 Phase installation requires (3) 3 gauge wires with a 10 gauge neutral wire, a suitable ground, and a clean circuit.

- List coming soon!

Looking for a specific part or accessory?

Creative, consistent engineering puts mix-and-match parts at the forefront — so customers won’t have to wait for an oddball part.

Choose Durable Commercial Dish Machines

Install the best commercial dish machines the market has to offer.